New Triple Detectable Food Grade Plastics

The Plastic Industry has changed the food processing industry in many ways. The machinery is bigger, lighter, quieter and safer than before plastic parts were commonly used. During the last decade, new and improved versions of plastic materials have been produced to enable the food processing industry to run machines faster, while also reducing maintenance cycles on these machines. By virtually eliminated the need to add of lubricants to moving parts and the regular pumping of grease into moving part fittings, the costs to use plastic has saved processors huge amounts of money.

Safety has always been a key element in the food processing industry, and the plastic products have therefore been supplied as FDA or NSF approved in almost all areas. Some very common plastics for food processing are HDPE, UHMW, Acetal, Delrin and Nylon. Each of these unique Performance Plastic materials is approved for use in food contact applications.

Additionally, during the last decade most food processors have upgraded their production lines and have added X-ray and/or Metal Detection equipment to these production lines. This has been a significant expense to these processors, and in many cases has found broken metal parts or other foreign matter in the food product.

There is one item that has been left out of this, and that is the plastic part used on the line.

New Solutions For Your Protection Using Detection

In 2010, the first in a new product line was first introduced; a new Metal Detectable Plastics. Since then, several additional new ‘detectable’ plastic materials have been released.

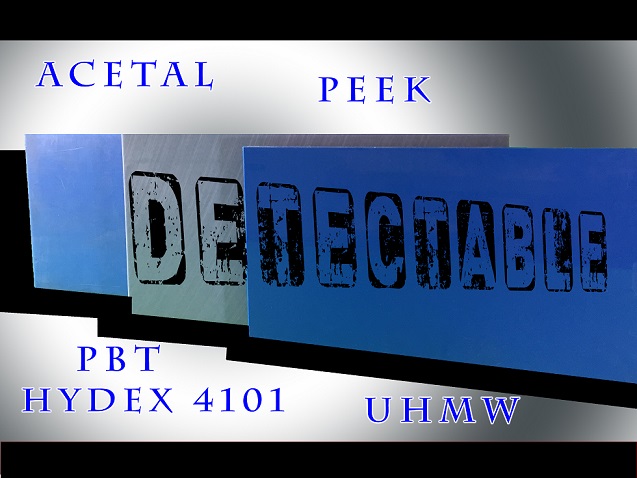

The materials that are now available in a detectable version include Acetal, PBT, UHMW and now PEEK. Most of these materials are produced with a Blue colorant making materials visible to optical detectors.

Rochling Plastics produces Metal Detectable (Dark Blue) Polystone® M MDT UHMW-PE and Sustarin® C MDT Acetal in Sheets and Rods.

Rochling also produces X-Ray Detectable (Medium Blue) Polystone® M XDT UHMW-PE, Sustarin® C XDT Acetal and SustaPEEK® XDT PEEK in Sheets and Rods.

For most applications, a user will choose a material based on physical properties and the type of detection desired.

Introducing Ultra Detectables

The newest detectable product in the market is Ensinger Plastics new Ultra Detectable Product Line.

These 3 materials are detectable in all three of the above detection methods.

Ensinger TECAFORM® UD Blue is an Acetal that is Blue in color and is also X-Ray and Metal Detectable.

In the middle of 2016, Ensinger released HYDEX® 4101 UD Blue (PBT) material that is Ultra Detectable. And to start off 2017, Ensinger has just released TECAPEEK® UD Blue that is also detectable with optical detectors, X-Ray and Metal Detection equipment.

The new TECAPEEK® UD Blue is excellent for use in demanding conditions. TECAPEEK® UD Blue has excellent resistance to a wide range of cleaning chemicals. It also has a heat deflection temperature of over 300ºF and a long term service temperature of over 450 ºF.

All of these detectable materials have been test for detection as small as 3mm, depending on equipment and processing speeds. Test materials for suitability.

Choosing Detectable Plastic

With several quality materials to choose from, the choice is a matter of required physical properties and economics.

The UHMW based materials are the least expensive, and will work in most applications requiring chemical resistance and temperature rating of less than 180 ºF continuous.

The Copolymer Acetal based materials are a low cost material that has good mechanical properties and continuous use at up to 300 ºF. This Acetal material is resistant to hot water, hydrocarbons and many solvents.

A relatively new entry into the detectable materials is Hydex 4101 UD Blue which is a PBT based product. This material has an increased physical properties and additional wear resistance associated with polyester based materials. Hydex 4101 UD Blue has resistance to cleaning chemicals, chlorine and caustics. This material performs well at higher temperatures, including a heat deflection temperature over 350 ºF at 66 psi.

A brand new release into the detectable market is a PEEK material. TECAPEEK UD Blue is a very chemical resistant based material that has a long term service temperature of 450 ºF, and performs very well in demanding environments.

While each of these unique materials are generally more expensive than the standard plastics normally used, the cost savings is very apparent when eliminating just one food contamination recall.

Bait Hotel produces superior live bait wells and bait buckets. Premium quality at discount prices. 31 models to choose from, and starting at just $69.00.

2240 S. Dupont Dr.

Anaheim, CA 92806

November 27, 2019 – New Configurations for Durable Live Bait Carriers

May 11, 2017 – New Plastic Family Targets Food Contamination Recalls