September 27, 2023

Boulder, Colorado - September 27, 2023 - PRESSADVANTAGE -

Surna Cultivation Technologies, a leading provider of value-added climate control solutions for the cannabis industry and controlled environment agriculture, has published an article outlining the advantages of implementing a 4-pipe Chilled Water System for optimizing cooling efficiency and maximizing energy savings in cultivation facilities.

A 4-pipe Chilled Water System is one of the most challenging types of systems to design and implement as it works to heat, cool, and dehumidify using a central piece of air-handling equipment. Cold water for cooling is provided by high-efficiency chillers powered by gas or electricity and heat is provided via heat recovery from the chillers, high-efficiency boilers, or even CHP (Combined Heat and Power).

While chilled water is circulated through the cooling coil for cooling and dehumidification, hot water is circulated through the reheat coil for reheating in dehumidification applications, or ambient heating as needed. To optimize the result, the 4-Pipe Chilled Water System modulates fan speeds and valve positions.

The spokesperson for Surna talks about some of the advantages of a 4-pipe Chilled Water System by saying, “In general, a 4-pipe chilled water system offers industrial quality equipment with longer life spans, outstanding precision, deep access to operational data, enormous flexibility placement and form factor of the various components, and extremely versatile redundancy options. In most cases, it also reduces the connected electrical load required for climate control considerably.”

However, Surna’s article also highlights the downsides of the system namely that it is complex to implement and properly maintain. It requires specialized expertise that not all cultivators will have access to and is among the most capital-intensive types of systems to implement.

When asked about what kind of facilities can benefit from a 4-pipe Chilled Water System, the spokesperson says, “The system is typically best applied in very large cultivation facilities, facilities with tight spatial constraints, facilities where the connected electrical load is a primary consideration, and facilities where data analysis and operational precision is of primary importance.”

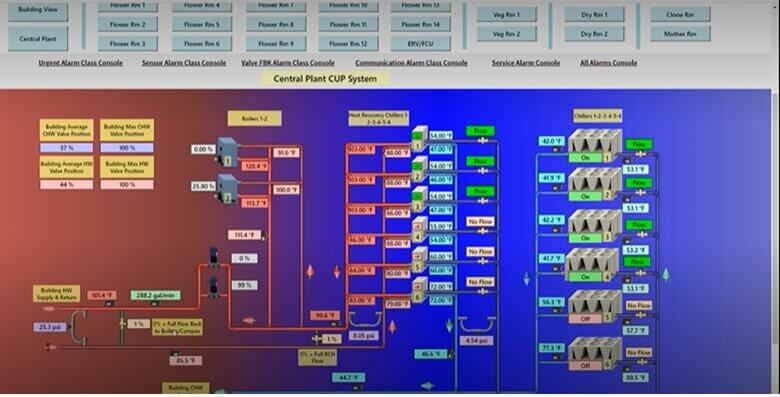

The article from Surna then goes on to share screenshots of an actual live facility that has been fitted with a 4-pipe Chilled Water System. The company urges readers to note the setpoints and the actual conditions that should be discernible in the screenshots to experts who have experience with indoor cultivation systems.

The spokesperson explains, “In the screenshot of the chiller plant for the case study, you will see the entire chilled water and hot water plant for the facility. The boilers and chillers that aren’t in active operation offer redundancy to the entire facility without the need to provide redundancy in each individual room. This also allows the load to be shared across multiple pieces of equipment, which keeps the equipment from running at full capacity 100% of the time, improving its overall longevity.”

The screenshots also offer a look into the wealth of information from the company’s Sentry IQ controls system, which is highly optimized for the cultivation industry and that the facilities maintenance team can use to optimize operations and troubleshoot the system when needed. Finally, the article invites readers to do a deep dive into the benefits of the 4-Pipe Chilled Water System by watching a video featuring Applications Engineer Ian Atkins and Director of Operations Kenneth Loshelder.

“Our main goal with the newest published article,” says the spokesperson, “is to start an informational series that explains the various technologies we have designed for indoor cultivators. It will showcase the tangible benefits of each of our products and equipment with case studies of live facilities that are already using our myriad systems. With the article on the 4-pipe Chilled Water System, which is the first in this series, we have kicked it off with one of the most challenging system designs. We urge you to head over to our website and follow us to be notified of future releases about other such technologies.”

Parties interested in learning more about chilled water pipe systems are encouraged to reach out to Surna Cultivation Technologies via their website at https://surna.com/contact/.

###

For more information about Surna Cultivation Technologies, contact the company here:

Surna Cultivation Technologies

Jamie English

(303) 993-5271

jamie.english@surna.com

385 S. Pierce Avenue, Ste. C

Louisville, CO 80027